How it's made

Everything you need to know about how your goods are made and attention to detail that goes into creating each item

100% handmade, no exceptions

All of the goods are made using classic leathercraft techniques without the involvement of heavy machinery, such as lasers and even sewing machines. That means that every piece of leather is hand-cut, each hole is hand-punched and every single stitch is also sewn with hands. Every single project on our table goes through the same treatment process.

-

Hand stitching

There is a saying that your goods will last as long as the stitching will last. To make ensure that our items will last a lifetime we hand-stitch every single piece of leather with highest quality Japanese braided thread.

-

Glueing

In order to preserve the integrity of the leather layers and uphold the polished look of your product, all layers are bonded together using odour-free water-based glue.

-

Edge and flesh treatment

Enhanced wear resistance is achieved through proper treatment of leather edges (and sometimes whole flesh of the leather piece) that are exposed to extensive contact with the external environment.

Hand stitching

Stitching affects and sometimes even defines the quality of the product.

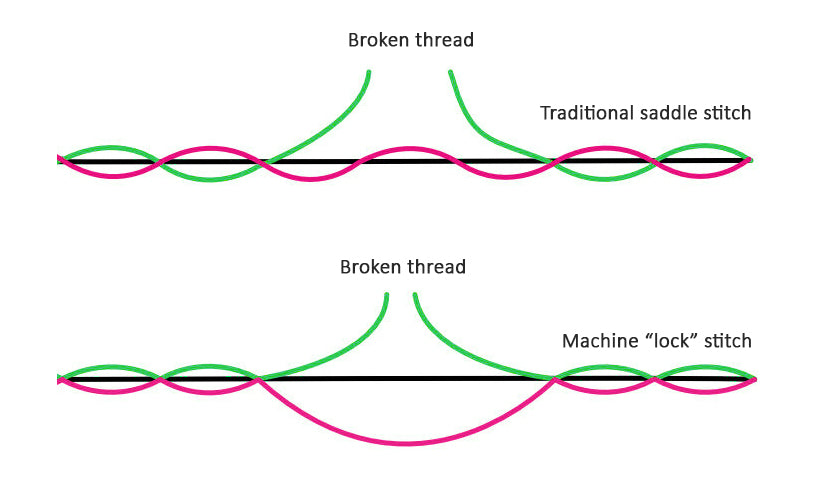

Sewing machine produced "lock" stitch is just two threads running in parallel. As soon as one thread breaks somewhere, the seam will come apart. With saddle stitch, on the other hand, if one thread breaks, the other thread will hold the piece together.

Here at ROCK LEATHER SCISSORS all products are hand sewn with a traditional saddle stitch. This method allows the craftsman to pull each stitch tightly, providing a stronger bond between the layers of the leather.

Not to mention, saddle stitch seam looks much more appealing and aesthethic.

Glueing

When there's a need to glue the leather together, we use professional contact glue - Intercom's Ecostick 1816B. Ecostick is a premium Italian water-based glue that does not stiffen the leather, is non-toxic, odour-free and transparent. It is considered more eco-friendly due to reduced VOC emissions, minimal product waste, and a small amount of glue required for a strong bond.

Edge and flesh treatment

The edges of leather are beveled using professional tools to eliminate sharp edges and prevent clinging. The edges are then treated with a non-toxic, water-based burnishing agent called Tokonole. Originating in Japan, it is utilized by leather craftsmen to seal leather fibers and apply a protective glossy finish to the edge, and sometimes to the whole flesh side of the leather piece.